How To Repair Pool Deck Coatings: 12 Point Concrete Coatings’ Approach

Pool decks take a beating from the sun, chlorine, and constant foot traffic. Over time, even the best coatings can show signs of wear, such as cracking, peeling, or fading. When this happens, many homeowners jump straight to a quick fix, but at 12 Point Concrete Coatings, we know that a true repair is about more than just patching a problem—it's about providing a lasting solution.

As a trusted choice for durable concrete coatings across Northwest Arkansas, we believe in doing the job right the first time. If you're seeing damage, here’s our expert guide to repairing pool deck coatings the right way, with a focus on long-term durability and safety.

Understanding Why Your Pool Deck Coating Is Failing

Before you can repair a coating, you must understand the root cause of the failure. Most common pool deck coatings, like standard epoxy or thin sealers, fail due to a few key factors:

UV Damage: Prolonged sun exposure in Northwest Arkansas can cause coatings to fade, chalk, and become brittle, leading to cracking and peeling.

Moisture Intrusion: Water from the pool, rain, and humidity can seep beneath a poorly applied or porous coating, causing it to lose adhesion and bubble or peel.

Chemical Exposure: Chlorine and other pool chemicals can degrade the coating over time.

Poor Preparation: The number one reason for coating failure is inadequate surface preparation. If the concrete isn't properly cleaned, profiled, and primed, the new coating won't bond correctly.

If your coating is failing, the right way to repair it is to remove the compromised material and replace it with a superior, high-performance system.

12 Point Concrete Coatings’ 4-Step Approach to Pool Deck Repair

When we approach a pool deck repair, our goal is not just to fix the visible damage but to install a system that helps prevent future issues. Our process involves a few critical steps that ensure a flawless, long-lasting finish.

Step 1: Full Removal and Surface Preparation

We start by mechanically grinding or shot-blasting the existing, failing coating and the top layer of concrete. This is the most crucial step. It removes all contaminants, old coatings, and weak concrete, exposing a clean, porous surface. This meticulous preparation creates an ideal profile, enabling our polyurea base coat to bond mechanically to the concrete.

Step 2: Crack and Spall Repair

Once the surface is clean, we thoroughly address cracks, spalls, and pitting. We use specialized, flexible repair materials that move with the concrete, helping reduce the likelihood of cracks telegraphing through the new coating.

Step 3: The Polyurea Base Coat Application

Unlike traditional repair methods that use less durable materials, we apply our industrial-grade polyurea base coat. This material is highly flexible, allowing it to accommodate the concrete's natural expansion and contraction due to temperature changes, a common issue in Northwest Arkansas’ climate. The base coat is the foundation of the system, providing the bulk of the strength and water resistance.

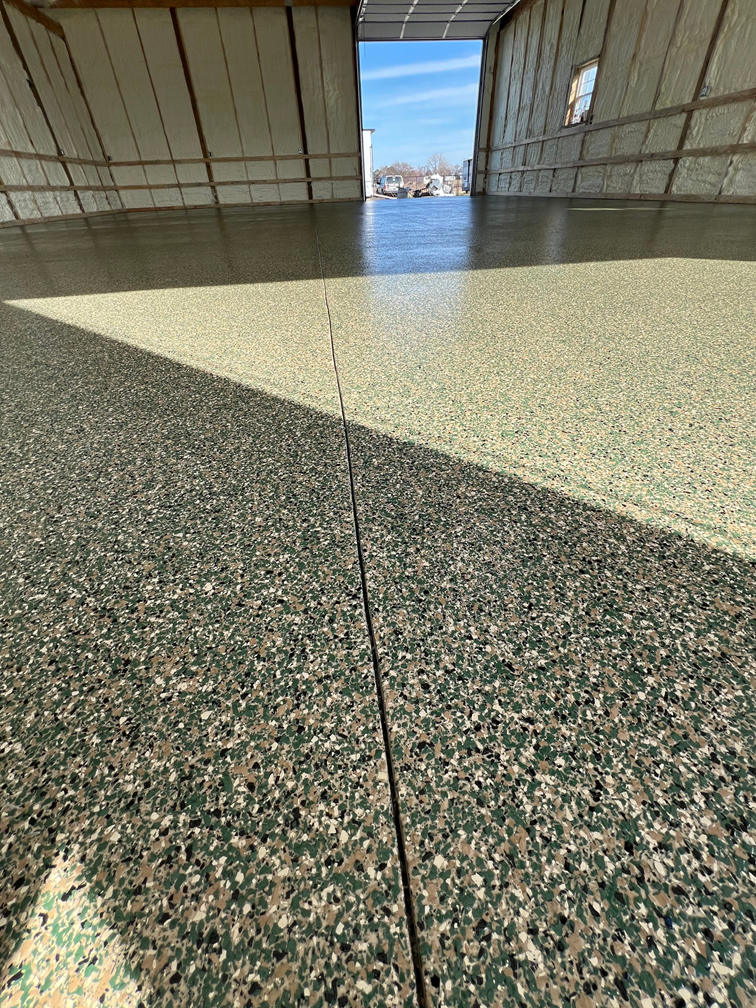

Step 4: Flake Broadcast and Top Coat

While the base coat is still wet, we broadcast decorative vinyl flakes to refusal. This step provides a beautiful, customizable look. More importantly, it adds a slip-resistant texture. For pool decks, safety is paramount, and our flake system ensures excellent traction, even when the surface is wet.

Finally, we seal the system with a clear, UV-stable polyaspartic top coat. This top coat is UV-resistant, meaning it will not yellow or fade under the sun. It also creates a non-porous, highly resistant barrier that withstands pool chemicals, stains, and moisture. Its exceptional performance is why we can confidently offer a 15-year residential warranty (subject to terms and proper maintenance) on our residential coatings.

Why Choose Polyurea Over Traditional Epoxy for Pool Decks?

Polyurea outperforms epoxy in several key areas.

| Feature | 12 Point Polyurea/Polyaspartic System | Traditional Epoxy |

|---|---|---|

| Strength | 4x Stronger than Epoxy | Prone to chipping and abrasion |

| UV Stability | Excellent (Will not yellow or fade) | Poor (Will yellow and degrade in sunlight) |

| Flexibility | High (Moves with concrete) | Low (Brittle, prone to cracking) |

| Cure Time | One-Day Installation | Multiple days required |

| Water Resistance | Non-porous, completely waterproof | Can be porous, allowing moisture intrusion |

Our polyurea coating can handle constant moisture, harsh chemicals, and direct sunlight. By choosing our system, you’re upgrading to a high-performance surface that will protect your pool deck for several years.

Experience the 12 Point Difference—Backed by Our 15-Year Warranty

Don't settle for temporary patches or inferior materials. If your pool deck coating is failing, let us provide you with a long-term, beautiful, and safe solution. Our family-owned company is proud to serve the Northwest Arkansas community, delivering quality you can trust and a 15-year warranty you can rely on.

Contact us today, and let’s end your pool deck problems for good.