What Are the Common Issues With Basement Floor Coatings?

After years of helping Northwest Arkansas homeowners transform their basement floors, we've seen every type of coating failure imaginable. From moisture-related bubbling to complete adhesion failures, these problems follow predictable patterns. More importantly, they're completely preventable when you understand what causes them.

Why Basement Floor Coating Problems Are More Common Than You Think

Basements pose unique challenges that make basement floor coatings more prone to failure than other areas of your home.

Constant Moisture

Moisture is the biggest culprit behind most coating failures. Unlike garage or living room floors, basement concrete is constantly exposed to ground moisture that can seep through the slab from below. This hydrostatic pressure pushes water vapor upward, creating problems for coatings that aren't designed to handle moisture. In Northwest Arkansas, where humidity levels can fluctuate significantly throughout the year, this challenge becomes even more pronounced.

Changing Temperatures

Temperature swings also play a major role in coating problems. Basements experience more dramatic temperature changes than climate-controlled living spaces, causing the concrete to expand and contract. When coatings can't flex with these movements, they crack, peel, or lose adhesion entirely.

The Most Frequent Basement Floor Coating Failures

12 Point Concrete Coatings encourages local Arkansas residents to familiarize themselves with these common issues so they can take action right away:

Peeling and Bubbling Issues

The most visible sign of coating failure is peeling or bubbling along the surface. This typically happens when moisture gets trapped beneath the coating, causing it to lift away from the concrete. Traditional epoxy coating for basement floors is particularly susceptible to this problem because epoxy doesn't handle moisture vapor transmission well.

You might notice small bubbles forming first, especially in corners or along walls where moisture tends to accumulate. Over time, these bubbles grow larger and eventually burst, leaving unsightly patches of exposed concrete.

Moisture-Related Problems

Moisture damage goes beyond surface bubbling. When water penetrates beneath a coating, it can cause:

- White chalky deposits (efflorescence)

- Discoloration or cloudy spots throughout the surface

- Soft or spongy areas where the coating has lost adhesion

- Mold or mildew in problem areas

Poor Adhesion and Durability

Even when moisture isn't the primary issue, many basement floor coating systems fail due to poor adhesion. This often results from inadequate surface preparation or choosing the wrong type of coating for the concrete's condition.

Your coating’s adhesion and durability are compromised if you notice:

- Coating that scratches or chips easily with normal use

- Edges lifting around the perimeter of the room

- Stubborn tire marks or scuff marks that can’t be cleaned easily

- Areas where the coating feels loose or hollow when walked on

- Complete delamination in high-traffic zones

How to Avoid These Common Coating Pitfalls

Prevention starts with understanding that not all coatings are the same. As experts in residential concrete services, here’s what we always tell our clients:

- Proper surface preparation is absolutely critical. The concrete must be thoroughly cleaned, any existing coatings or sealers removed, and the surface properly profiled to ensure mechanical adhesion.

- Moisture testing should be performed before applying any coating. This involves checking the moisture content of the concrete and the vapor transmission rate.

- Choosing the right coating material is another vital step. While traditional epoxy basement floor coating systems are popular, they often struggle with basements' high moisture levels and fluctuating temperatures.

What Is the Best Coating for Basement Floors?

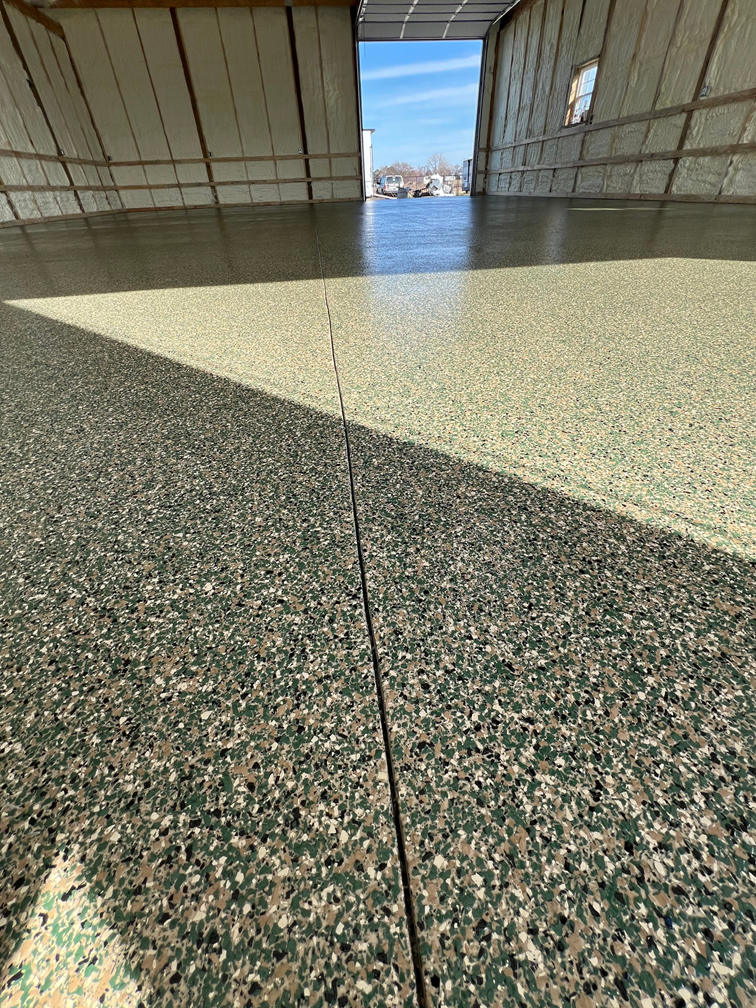

The best coating for basement floors is polyurea and polyaspartic coatings, the current gold standard. These advanced materials directly address common coating problems. While epoxy coatings often bubble or peel as ground moisture passes through concrete, polyurea and polyaspartic systems prevent that problem by tolerating moisture vapor transmission.

They also offer superior flexibility, allowing them to move with the concrete as it expands and contracts with changing temperatures. This prevents the cracking and delamination that affect rigid coating systems.

From a durability standpoint, these coatings bond more strongly to properly prepared surfaces. While traditional epoxy might last 3 to 5 years before showing signs of failure, quality polyurea and polyaspartic systems maintain their performance for 15 years or more when properly installed.

Contact Us for Worry-Free Basement Floor Coatings

Don't let past coating failures or horror stories discourage you from creating the basement space you want. With the right approach and high-quality materials, your basement floor can become a durable and attractive surface that lasts for years.

The team at 12 Point Concrete Coatings has been solving these exact problems for homeowners throughout Northwest Arkansas, and we'd love to help you avoid the common pitfalls that lead to coating disappointment. Every system we use is designed to handle Northwest Arkansas basements, standing up to moisture, temperature swings, and daily wear for lasting results. Call us today for expert guidance and professionally installed basement coatings.